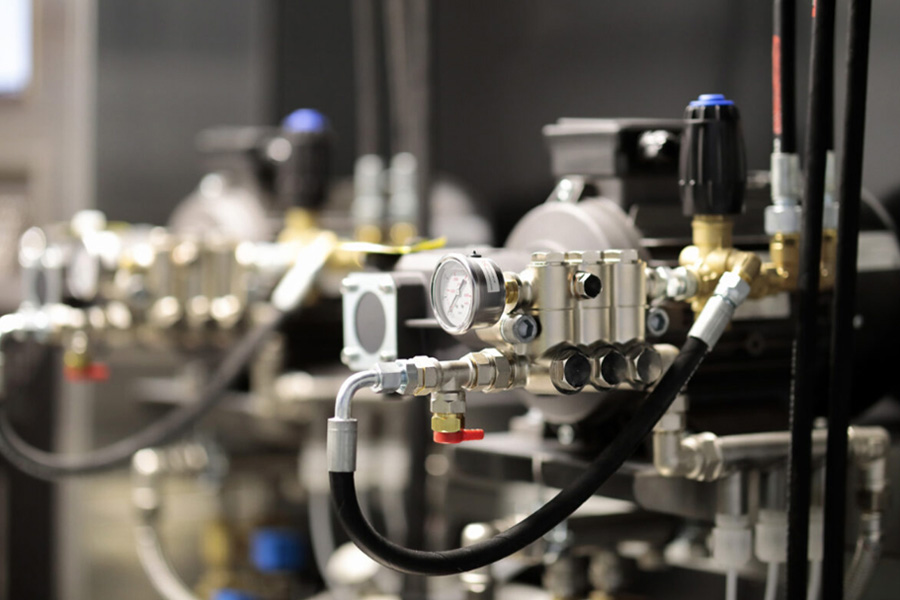

Industrial hydraulic hoses play an indispensable role in the world of heavy-duty applications. From construction sites to mining operations, these robust and flexible conduits are essential for the seamless operation of hydraulic systems. Understanding their significance, applications, and the benefits they offer is crucial for those involved in industries reliant on heavy machinery.

Understanding Industrial Hydraulic Hoses

Industrial hoses are specifically designed to transport hydraulic fluid between various components within a hydraulic system. Constructed from a combination of synthetic rubber, thermoplastic, and reinforced materials such as steel wire, these hoses are engineered to withstand extreme pressures and harsh environments. The resilience and flexibility of hydraulic hoses make them suitable for a wide range of applications, from construction equipment to industrial machinery.

Enhancing Efficiency in Heavy-Duty Applications

Efficiency in heavy-duty applications is paramount, as it directly impacts productivity and operational costs. Hydraulic hoses contribute significantly to this efficiency in several ways:

High-Pressure Performance

One of the primary advantages of hydraulic hoses is their ability to handle high-pressure fluids. In heavy-duty machinery, hydraulic systems often operate under immense pressure. Industrial hoses are designed to endure these high pressures, ensuring a consistent flow of hydraulic fluid without leaks or bursts. This reliability translates into uninterrupted operation, minimising downtime and enhancing overall efficiency.

Flexibility and Adaptability

The flexibility of industrial hydraulic hoses is another factor that enhances efficiency. These hoses can be easily routed around obstacles and through tight spaces, allowing for more compact and efficient hydraulic system designs. This adaptability is particularly valuable in applications where space is limited, such as in construction equipment or agricultural machinery. The ability to bend and manoeuvre without compromising performance ensures that the machinery operates at optimal efficiency.

Durability and Longevity

Industrial hoses are built to last, even in the most demanding environments. Their construction materials are chosen for their resistance to abrasion, chemicals, and extreme temperatures. This durability reduces the frequency of hose replacements, lowering maintenance costs and further contributing to operational efficiency. When hydraulic hoses are used, equipment can remain in service for longer periods, reducing the need for frequent maintenance interventions.

Ensuring Safety in Heavy-Duty Applications

Safety is a critical concern in any industrial setting, particularly where heavy machinery is involved. Industrial hoses play a vital role in ensuring the safety of operations in several ways:

Leak Prevention

Leak prevention is a key aspect of hydraulic system safety. Hydraulic fluid leaks can lead to equipment malfunctions, environmental contamination, and even pose fire hazards. Industrial hoses are designed with multiple layers of reinforcement to prevent leaks, ensuring that the hydraulic fluid remains contained within the system. This leak prevention is essential for maintaining a safe working environment and avoiding potential hazards.

Burst Resistance

The potential for hose bursts is a significant safety concern in high-pressure applications. Industrial hydraulic hoses are engineered to withstand extreme pressures and prevent bursts, even under the most demanding conditions. This burst resistance is critical for protecting both the machinery and the operators. In the event of a hose failure, the consequences can be catastrophic, leading to severe injuries or fatalities. The robust construction of hydraulic hoses mitigates this risk, ensuring safer operations.

Proper Maintenance and Inspection

While hydraulic hoses are designed for durability, regular maintenance and inspection are essential to ensure their continued performance and safety. Routine checks for signs of wear, such as abrasions, cracks, or leaks, can identify potential issues before they become critical. Proper maintenance practices, including timely replacements and repairs, contribute to the longevity and safety of the hydraulic system. Ensuring that industrial hoses are in optimal condition is a proactive measure that enhances both efficiency and safety.

The Impact on Various Industries

The impact of hydraulic hoses extends across numerous industries. In construction, they power the hydraulic systems of excavators, bulldozers, and cranes, enabling the efficient movement of heavy materials. In agriculture, these hoses facilitate the operation of tractors, harvesters, and other equipment, ensuring that farming tasks are completed with precision and speed. In mining, the robust construction of hydraulic hoses is essential for the reliable performance of drilling rigs, loaders, and other heavy machinery used in extracting valuable resources.

Conclusion

In conclusion, industrial hydraulic hoses are indispensable components in heavy-duty applications, offering enhanced efficiency and safety. Their ability to withstand high pressures, flexibility, and durability make them crucial for maintaining optimal performance in hydraulic systems. By preventing leaks and bursts, these hoses ensure the safety of both the machinery and the operators. Regular maintenance and inspection further contribute to their reliability, making industrial hoses a cornerstone of efficient and safe operations across various industries. Understanding their importance and ensuring their proper use can lead to significant improvements in productivity and safety in heavy-duty applications.